Introduction to Rural Japan’s Labor Crisis

In rural Japan, a staggering demographic shift is reshaping the economic landscape, with over 30% of the population in nonurban areas now aged above 65, creating an unprecedented labor shortage that threatens the foundation of small and midsize enterprises (SMEs). These businesses, which form the backbone of local economies, especially in sectors like manufacturing and agriculture, face declining productivity and questions about their long-term sustainability due to the dwindling workforce. How can rural regions adapt to such profound challenges? This report delves into Japan’s strategic push to integrate robotics as a transformative solution, exploring government initiatives, real-world impacts, and the hurdles that lie ahead.

Government-Led Robotics Revolution

Strategic Programs and Partnerships

The Japanese government, through the Ministry of Economy, Trade and Industry, has taken decisive steps to support rural SMEs by promoting robotics as a countermeasure to labor shortages. A key pillar of this effort is the Robotics & Regional Initiative Networking Group (RING Project), launched with a coalition of approximately 30 local governments and ministries. With an annual membership fee of around $649, this initiative focuses on sharing best practices, conducting training sessions, and organizing events to foster innovation and address local challenges through technology.

Beyond national efforts, local governments are playing a pivotal role in creating tailored ecosystems for robot adoption. For instance, Sagamihara in Kanagawa Prefecture has emerged as a leader by facilitating about 100 robot integrations annually, setting a benchmark for other regions. Advisory bodies and specialized training programs further assist SMEs in navigating the complexities of digital transformation, ensuring that businesses can adapt to new systems without being overwhelmed by technical demands.

Tangible Outcomes and Case Studies

The impact of these initiatives is evident in success stories across rural Japan. Arikawa Seisakusho, based in Kanazawa, Ishikawa Prefecture, reported a 9% increase in production capacity after automating key processes with robotics. This boost not only improved efficiency but also positioned the company as a forward-thinking employer, attracting younger talent to a traditionally aging workforce.

Moreover, these achievements are more than isolated wins; they offer replicable models for other SMEs. Data from early adopters shows consistent productivity gains and enhanced workforce appeal, suggesting that robotics can redefine rural businesses as modern, innovative workplaces. Such transformations highlight the potential for broader economic revitalization if scaled effectively across regions.

Barriers to Robotics Integration

Financial and Technical Obstacles

Despite the promise of robotics, rural SMEs face significant barriers to adoption, with high upfront costs often proving prohibitive for businesses operating on tight budgets. Many owners lack the technical expertise required to implement and maintain robotic systems, creating a steep learning curve that can deter investment. Resistance to organizational change further complicates the transition, as long-standing practices are deeply ingrained in these enterprises.

Operational Challenges and Mismatches

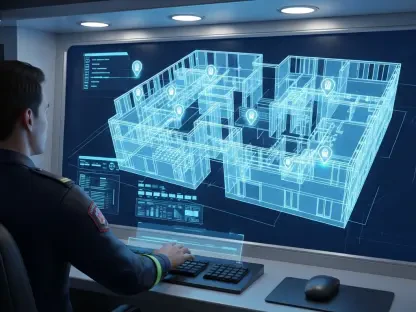

Common pitfalls during implementation include cost disputes with vendors and mismatched expectations about the capabilities of robotic systems. These issues can lead to project failures, undermining confidence in technology as a viable solution. For SMEs unfamiliar with advanced tools, the prospect of digitalizing operations and redefining workflows often feels daunting, adding another layer of complexity to an already challenging process.

Potential Solutions to Ease Adoption

Addressing these hurdles requires a multifaceted approach, starting with government subsidies to offset initial costs and make robotics more accessible. Tailored training programs can bridge the knowledge gap, equipping SME owners and employees with the skills needed to manage new systems. Additionally, personalized support from advisory bodies can help align expectations and ensure that technology investments deliver measurable value to rural businesses.

Policy and Support Ecosystems

National Guidelines and Incentives

The Ministry of Economy, Trade and Industry has established a robust framework of policies and guidelines to encourage robotics integration among rural SMEs. These measures include financial incentives and clear directives on how businesses can access support for automation projects. Such national efforts aim to create a cohesive strategy that aligns with the unique needs of nonurban economies.

Local Government Contributions

Local governments complement these policies by offering funding and technical assistance, creating nurturing environments for technology adoption. Regions like Kitakyushu in Fukuoka Prefecture actively seek to learn from other areas’ public-sector strategies, fostering a culture of collaboration. This localized support ensures that SMEs receive assistance tailored to their specific operational and regional challenges.

Compliance and Standardization Efforts

Compliance with safety standards and regulatory requirements for robotic systems remains a critical focus, particularly in industrial settings where worker safety is paramount. Collaborative initiatives like the RING Project play an essential role in standardizing best practices, ensuring that implementations meet necessary benchmarks. This emphasis on regulation helps build trust in robotics as a safe and reliable solution for rural enterprises.

Emerging Trends and Future Outlook

Innovations Tailored for SMEs

Looking ahead, advancements in robotics technology are increasingly geared toward affordability and user-friendliness, making them more viable for SMEs with limited resources. Compact, cost-effective systems are being developed to suit the scale of smaller operations, reducing the financial burden of adoption. These innovations promise to democratize access to automation in rural areas over the coming years.

Scaling Success Through Collaboration

Regional collaboration offers a pathway to scale successful models nationwide, with areas like Sagamihara and Kitakyushu serving as inspiration for broader implementation. By sharing knowledge and resources, rural regions can collectively build momentum for robotics adoption, amplifying the impact of individual successes. This cooperative approach could redefine the technological landscape of nonurban Japan.

Long-Term Economic Impacts

The long-term implications for rural economies are profound, with robotics poised to drive job creation, productivity growth, and economic resilience. While automation may initially replace certain manual tasks, it also opens opportunities for new roles in technology management and innovation. Combined with global technological trends and ongoing demographic challenges, these developments will shape the trajectory of rural Japan’s economic future.

Reflecting on Progress and Next Steps

Looking back, Japan’s initiative to integrate robotics into rural SMEs through government and local collaboration has tackled labor shortages by enhancing productivity and modernizing workplaces. The tangible benefits seen in pioneering businesses underscore the potential of this approach, even as widespread adoption faces practical and financial obstacles.

Moving forward, actionable steps must prioritize sustained support beyond initial subsidies, focusing on building shared expertise through platforms like the RING Project. Strengthening regional partnerships can accelerate learning and innovation, while accessible training programs will empower more SMEs to embrace technology. Ultimately, fostering a network of mutual support and continuous improvement will be key to ensuring that rural businesses not only survive but thrive amid demographic challenges.