The intricate dance of global commerce and technological sovereignty is being played out on the microscopic circuits of semiconductors, and India, a nation consuming billions of dollars’ worth of these critical components, is now making a historic bid to join the performance. For decades, the country has been a spectator, watching as its industries grew increasingly dependent on a complex international supply chain. Now, with a combination of massive government incentives and landmark private sector investments, India is stepping onto the world stage, determined to transform itself from a chip consumer into a chip creator. This ambitious pivot is not merely an economic strategy; it is a declaration of intent, a high-stakes gamble to secure a place in the most technologically demanding industry humanity has ever conceived.

The urgency behind this national mission is underscored by stark economic realities and pressing geopolitical imperatives. As India’s digital economy expands at a breakneck pace, its reliance on foreign-made chips has become a significant vulnerability, creating supply chain risks and a widening trade deficit. The government’s multi-billion-dollar push aims to address this imbalance, fostering an ecosystem that can not only meet burgeoning domestic demand but also position India as a reliable alternative in a global supply chain increasingly fractured by geopolitical tensions. The question is no longer whether India should pursue this goal, but whether its strategy, resources, and resolve are sufficient to overcome the monumental challenges that lie ahead in this global “moonshot” endeavor.

The High Stakes of Chasing Self Reliance

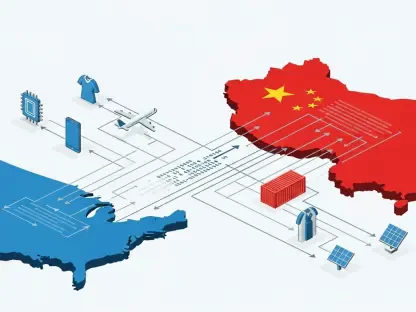

The sheer scale of India’s dependence on foreign semiconductors paints a sobering picture of the challenge at hand. Last year, the nation’s chip imports surged by an astonishing 36 percent, reaching nearly $24 billion and continuing to grow at a rate of 20 percent year-on-year. This figure, representing approximately three percent of India’s total import bill, highlights a critical economic vulnerability. The overwhelming majority of these essential components originate from a handful of countries, with China remaining the leading supplier. This reliance leaves India’s burgeoning electronics, automotive, and defense industries susceptible to global supply chain disruptions, price volatility, and the geopolitical whims of other nations, a reality that became painfully clear during the global chip shortages.

Building a domestic semiconductor industry to counteract this dependency is an undertaking of epic proportions. It involves creating a trillion-dollar industry from a near-zero base in fabrication, a domain where success is measured in nanometers and capital expenditure is measured in tens of billions of dollars. The global landscape is dominated by deeply entrenched players: the United States leads in the high-value discipline of chip design, Taiwan stands as the undisputed champion of advanced manufacturing, and China has rapidly expanded its dominance in assembly and packaging. For India to carve out a meaningful niche, it must not only attract immense capital and cutting-edge technology but also cultivate a highly skilled workforce and build the vast, complex infrastructure of reliable power, pure water, and logistics that this industry demands.

Deconstructing a Grand Strategic Pivot

At the heart of India’s semiconductor ambition lies Prime Minister Narendra Modi’s flagship $10 billion incentive program, a policy initiative designed to be the cornerstone of a much broader economic vision. This program is more than just a financial subsidy; it is a strategic signal to the world that India is serious about becoming a major player in high-tech manufacturing. By offering substantial financial support, including direct 50 percent subsidies for new fabrication plants, the government aims to de-risk the massive upfront investments required and lure global leaders in the semiconductor industry to establish operations within its borders. This policy is the central engine driving what many hope will be India’s technological renaissance.

This national push is strategically timed to capitalize on the global “China Plus One” trend, a widespread corporate movement to diversify supply chains and reduce over-reliance on Chinese manufacturing. As international firms seek to build resilience and mitigate geopolitical risks, India is positioning itself as a stable, democratic, and economically viable alternative. The government’s strategy is not to directly compete with or displace existing manufacturing hubs overnight, but rather to capture the significant incremental growth projected for the industry. This pragmatic approach recognizes the deep roots of the existing supply chain while focusing on securing a substantial share of future demand.

The ultimate objective is to serve both a rapidly expanding domestic market and the global export arena. With the global semiconductor market projected to soar from around $650 billion to over $1 trillion by 2030, and India’s own domestic market expected to double from $50 billion to $100 billion in the same timeframe, the opportunity is immense. By building local capacity, India aims to improve its trade balance, enhance the competitiveness of its chip-dependent industries, and create a self-sustaining ecosystem that fuels innovation. The goal is to transform from a passive consumer into an active and influential participant in the global technology value chain.

From Blueprints to Reality on the Ground

India’s strategy begins with a pragmatic and calculated first step: targeting the less complex but highly essential segments of the market. Rather than immediately pursuing the cutting edge, the initial focus is on “mature” or “legacy” chips—those built on nodes ranging from 28 nanometers to 110 nanometers. While not used in the latest smartphones or AI accelerators, these chips are the workhorses of the modern economy, indispensable for automobiles, industrial machinery, and a vast array of consumer electronics. Alongside this, India is heavily investing in the Assembly, Testing, and Packaging (ATP) sector, which is considered a more accessible entry point due to its lower capital requirements and less demanding technological barriers, providing a foundation upon which a more advanced industry can be built.

The centerpiece of this entire initiative is taking shape in the western state of Gujarat: India’s first commercial semiconductor foundry. This landmark $11 billion venture is a collaboration between one of India’s largest conglomerates, the Tata Group, and Taiwan’s Powerchip Semiconductor Manufacturing Corporation (PSMC). The project, which is set to receive more than half of the government’s $10 billion incentive fund, is a monumental step forward after numerous previous attempts to establish a commercial fabrication plant failed. With technology transfer and construction assistance from PSMC, the plant could become operational as early as December 2026, marking a pivotal moment in the nation’s industrial history. Underscoring its strategic importance, American chip giant Intel has already been brought on as a potential customer, signaling international confidence in the project’s viability.

While the foundry represents the most ambitious part of the plan, a parallel effort is underway to build a robust ATP ecosystem. Major investments are flowing into this sector, including a $2.7 billion facility from the Idaho-based Micron Technology and a $3.3 billion plant by the Tata Group in the state of Assam. However, these large-scale projects have faced significant delays, with Micron’s production timeline pushed to the “latter half of this decade” and Tata’s plant delayed to April 2026. In stark contrast, smaller, more agile players are demonstrating quicker progress. Kaynes Semicon, for instance, has already shipped its first batch of sample chip modules to a client in California, providing a symbolic but important early victory for India’s nascent industry.

Cautious Optimism Meets a Sobering Reality Check

The flurry of activity has generated what many analysts describe as “unprecedented momentum” for India’s semiconductor ambitions. The combination of strong political will, substantial private sector commitment from a respected entity like the Tata Group, and strategic international partnerships has created a tangible sense of progress. For the first time, India is moving beyond mere aspiration and into the complex phase of execution, with construction underway and tangible timelines in place. This progress has shifted the narrative from “if” to “how,” but experts universally caution that the journey ahead remains long, arduous, and fraught with immense challenges.

This cautious optimism is grounded in a realistic assessment of India’s current position in the global hierarchy. Stephen Ezell of the Information Technology and Innovation Foundation (ITIF), a prominent technology policy think tank, tempers expectations by stating that it is “highly unlikely” a domestic Indian firm will be competitive in cutting-edge fabrication—the sub-7-nanometer nodes required for advanced AI and high-performance computing—anytime in the near future. This expert consensus suggests that while India can succeed in establishing a robust presence in mature nodes and packaging, reaching the technological frontier will require a multi-decade effort and a far deeper integration with global technology leaders.

Perhaps the most sobering reality check comes from a simple comparison of financial firepower. India’s $10 billion incentive program, while a historic investment for the country, is dwarfed by the massive government subsidies being deployed by its competitors. The United States has committed $53 billion through its CHIPS and Science Act, and China has funneled an estimated $48 billion into its own semiconductor industry, with more likely to come. This global subsidy race creates an intensely competitive environment for attracting the mobile capital and coveted technology of multinational chipmakers. To move beyond its initial foray and compete for more advanced manufacturing facilities, India will need to demonstrate that its financial incentives are competitive on a global scale.

The Four Hurdles on the Road Ahead

Looking forward, the initial $10 billion fund must be seen not as a finish line but as a starting pistol. To sustain momentum and graduate from mature nodes to more advanced technologies, India will almost certainly need to scale up its financial incentives. A second, and likely larger, round of government support is already reportedly under consideration. This sustained financial commitment is crucial not only to fund domestic projects but also to compete for the next wave of global investment as chipmakers decide where to build the fabs of the future. The scale of investment required in this industry means that policy consistency and long-term financial backing are non-negotiable prerequisites for success.

Beyond funding, India faces the critical imperative of attracting a “big fish”—a leading international technology partner willing to engage in a deep partnership for advanced node manufacturing. Securing such a collaboration with a firm like TSMC, Samsung, or Intel for cutting-edge fabrication is the holy grail, but it requires more than just subsidies. It demands fundamental and durable improvements to the entire business ecosystem. This includes guaranteeing an uninterrupted supply of ultra-pure water and highly reliable power, streamlining complex regulations and customs procedures, and ensuring a stable, predictable tariff policy. These foundational elements are often more decisive for long-term investment decisions than short-term financial incentives.

Simultaneously, India must defend its one existing and significant advantage in the semiconductor value chain: its world-class talent in chip design. Indian engineers already constitute an estimated 20 percent of the global chip design workforce, a powerful asset that forms the intellectual backbone of the industry. However, this strength is under threat from rising competition. Nations like Malaysia and China are offering aggressive tax incentives to lure multinational design and R&D centers away. A recent Indian government policy, criticized for limiting incentives to domestic firms in an effort to promote local intellectual property, risks inadvertently pushing multinational design work to more welcoming shores, potentially eroding the very ecosystem India needs to build upon.

Finally, the entire endeavor is subject to the unpredictable currents of geopolitics. While India’s new facilities will primarily serve the burgeoning domestic market, a key part of their business model relies on exporting to partners in the U.S., Japan, and Taiwan. The potential for a future U.S. administration to impose steep tariffs on foreign-made electronics, including semiconductors, presents a significant risk to this export strategy. Furthermore, existing trade friction between Washington and New Delhi over unrelated issues creates a climate of uncertainty that could complicate the deep, trust-based partnerships needed with American firms, which collectively control over half of the global semiconductor market. Navigating this complex geopolitical landscape will be just as critical as mastering the technical challenges of fabrication.

In its quest to join the global chip race, India had laid a foundation built on strong political will and significant private sector commitment. The strategic decision to initially focus on mature chips and packaging represented a logical and pragmatic approach, designed to build institutional capacity while satisfying the immense and growing demand of its domestic economy. This path offered a foothold in one of the world’s most critical industries. However, the journey from this starting point to becoming a global semiconductor power was recognized as a “moonshot” endeavor, one whose ultimate success depended on an unwavering ability to sustain policy momentum, dramatically scale investment to compete on the world stage, and meticulously cultivate a business-friendly ecosystem capable of attracting and retaining the world’s best technology and talent.