Today, we’re diving into the cutting-edge world of waste management with Donald Gainsborough, a visionary leader at Government Curated and a political savant who has been instrumental in shaping policies around innovative recycling technologies. With his deep expertise in legislative frameworks and community engagement, Donald has been at the forefront of integrating AI-driven solutions into public waste systems. Our conversation explores how artificial intelligence is transforming the way we handle trash, the remarkable outcomes of pilot projects in places like southeastern Virginia, the challenges of shifting mindsets, and the future of safer, more efficient recycling practices. Join us as we uncover the stories and strategies behind this revolutionary shift in an industry often overlooked but vital to our environment.

How did the partnership between southeastern Virginia’s waste authority and AI technology providers come about, and what was a defining moment from the pilot project in Portsmouth that really highlighted its potential?

The partnership kicked off because there was a pressing need to rethink waste management in the region, especially with landfills filling up faster than anyone wanted. The Southeastern Public Service Authority was looking for innovative ways to extend landfill life and boost recycling rates for over 1.2 million residents, and AI presented a game-changing opportunity after initial discussions around sustainable tech solutions. I remember during the early talks, there was this mix of excitement and skepticism—could machines really sort trash better than humans? But the two-year pilot in Portsmouth turned heads. One moment that stands out is when we saw the system process 150 tons of municipal waste in a single day, pulling out recyclables from what looked like an impossible mess of bagged trash. I was there on the floor, watching the conveyor belts whir and the pneumatic jets zap items into the right bins—it was like watching a sci-fi movie come to life. That day, we realized this wasn’t just a concept; it was a scalable solution that could redefine regional waste strategies.

What struck you most about the results from the Portsmouth pilot, where 50% to 60% of material was diverted from landfills, and how do those numbers stack up against traditional methods?

Honestly, I was floored by the sheer volume of material we diverted—50% to 60% is no small feat when you’re dealing with mixed, messy municipal waste. What hit me hardest was seeing how much organic waste, stuff like food scraps that usually just rots in landfills, was being captured for better use. I recall one batch where we recovered a surprising amount of compostable material that would’ve been buried otherwise; it was a reminder of how much value we’re literally throwing away. Compared to traditional manual sorting, these numbers are night and day—manual methods might achieve 10-15% diversion on a good day, and that’s with workers risking injury. With AI, we’re not just saving materials; we’re saving time and keeping people safe. It’s a stark contrast, and standing in that facility, smelling the damp waste but seeing the clean separation, it felt like we were finally winning a long battle.

Convincing communities to embrace AI in waste sorting must have come with hurdles. Can you share a personal experience of overcoming doubt, and how do you see recycling goals evolving in the coming years?

Oh, absolutely, there was a lot of pushback at first. Many folks in the community thought AI was some expensive gimmick that wouldn’t deliver, and I get it—change is hard, especially in something as gritty as waste management. I remember a town hall meeting in one of the cities we serve; a local resident stood up and asked why we were spending money on robots when people needed jobs. I shared how this tech wasn’t about replacing workers but making their roles safer and more skilled, and I invited him to see the pilot site in action. After he watched the system pull recyclables out of shredded trash with pinpoint accuracy, he turned to me with this wide-eyed look and said, “Okay, I’m sold.” That moment stuck with me—it showed how seeing is believing. Looking ahead, I think our goal of a 20% recycling rate is just the start; in five years, with broader adoption, I see us pushing toward 30-40%, especially as we refine the tech and educate more residents to become active recyclers. It’s about building trust and momentum together.

The shift from manual sorting to AI-driven systems has been called revolutionary, especially for worker safety. How has this changed the daily lives of workers, and can you recount a specific instance where this tech made a difference?

It’s been a complete transformation for workers, moving them from physically taxing and risky roles to ones where they’re systems engineers, fine-tuning machines and ensuring quality. Instead of digging through trash with gloves and masks, facing sharp objects or chemicals, they’re now at control panels, monitoring data in real time. I think of a worker I met during the pilot phase—he’d been sorting manually for over a decade and had a scar on his arm from a piece of jagged metal that cut through his gear. After the AI system was implemented, he told me how relieved he was to not have to face that danger daily; one day, the system flagged a hazardous chemical container that would’ve been a nightmare to handle by hand, and he just watched it get diverted safely. That story hit home for me—the relief in his voice, the weight lifted off his shoulders. Training for these new roles isn’t overnight; it involves learning software interfaces and troubleshooting, but it’s empowering workers with skills for the future, which is incredibly rewarding to see.

With only 21% of recyclable materials captured in the US, and Virginia losing over 1 million tons yearly, how is AI tackling this massive gap, and can you walk us through a real-world example of its impact?

The low capture rate of recyclables—just 21% nationwide—is a crisis, and losing over a million tons in Virginia alone shows how broken the system has been. AI steps in by identifying and separating materials with a precision humans can’t match, especially at scale. The process is fascinating: cameras scan waste on a conveyor belt after it’s shredded for spacing, AI algorithms recognize items by shape and material, and then air jets push them into the correct bins—think plastics to one side, organics to another. I’ll never forget a case in one of our facilities where we recovered a huge batch of mixed plastics that would’ve been landfilled because manual sorting missed them. We’re talking thousands of pounds diverted in a week, all because the system could spot tiny differences in texture and color. Seeing those bins fill up with materials bound for reuse, not burial, gave me a rush of hope. It’s not just about numbers; it’s about turning a tide of waste into resources, one conveyor belt at a time, and showing communities what’s possible.

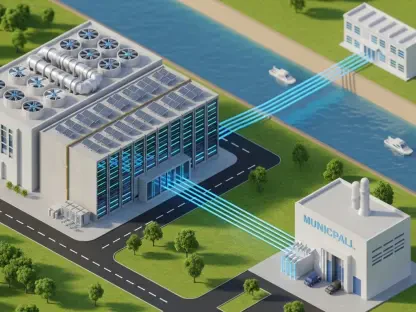

As new facilities are being built to process massive amounts of recycling annually, what key lessons from past projects are guiding these efforts, and what might a typical day look like at one of these sites?

Every project teaches you something, and one big lesson we’ve taken to heart is the importance of community buy-in before scaling up tech like this. In past pilots, we learned that without clear communication about how AI boosts efficiency and safety, you risk resistance, so now we prioritize outreach from day one. For a new facility processing over 60,000 tons of recycling a year, we’re applying that by hosting open houses even during construction. Picture a typical day once it’s running: the site hums early with trucks rolling in, unloading single-stream recycling onto massive tip floors. Workers at control stations monitor screens as shredded waste moves through belts, AI cameras clicking and jets hissing to sort materials into neat piles—plastics, paper, metals—all while the air carries that distinct, earthy smell of processed waste. Engineers tweak algorithms on the fly to handle odd items, and by afternoon, you see bins overflowing with recyclables ready for repurposing. It’s organized chaos, but with a purpose, and we’re already planning to replicate this model in other regions by tailoring outreach to local needs.

AI in waste management has been hailed as a game-changer, especially since manual sorting was often too costly and risky. What’s the most surprising benefit you’ve discovered, and how do you envision public perception of waste sorting changing over time?

Beyond the obvious wins like safety and cost reduction, the most surprising benefit for me has been how AI has turned waste into a conversation starter about sustainability. I didn’t expect communities to get so engaged, but I recall a small town near one of our pilot sites where, after seeing 50% of their trash diverted, residents started organizing local cleanups to feed more recyclables into the system. I was there for one event, picking up litter with kids who were thrilled to know their soda cans wouldn’t just rot in a dump—it was heartwarming to see that shift in mindset. Over the long term, I think public perception will move from viewing waste sorting as a dirty, invisible chore to a high-tech, community-driven effort. People will start seeing trash as a resource, not a burden, especially as they witness AI pulling value from what they discard. The more we share these success stories, the more I believe folks will embrace recycling as a point of pride, not just a duty.

What’s your forecast for the future of AI in waste management over the next decade?

I’m incredibly optimistic about where this is heading over the next ten years. I foresee AI becoming the backbone of waste management across North America, not just in niche projects but as a standard in every major municipality, potentially diverting millions more tons from landfills. We’ll likely see systems get even smarter, identifying niche materials like rare plastics or electronics with even greater accuracy, and integrating with smart city initiatives to track waste from households to processing plants. The challenge will be funding and policy support, but with proof points like doubling landfill life and hitting higher recycling rates, I think we’ll see a groundswell of investment. Imagine walking into a facility a decade from now and seeing a near-zero waste output—that’s the dream driving me forward, and I believe we’re on the cusp of making it real.