The automation instrumentation market is experiencing significant growth, driven by various factors that enhance efficiency, precision, and safety in industrial processes. This article delves into the key drivers behind this growth, examining the role of technological advancements, market demands, and industry trends.

Technological Advancements

Integration of IoT and Industry 4.0

The integration of the Internet of Things (IoT) and Industry 4.0 technologies is revolutionizing the automation instrumentation market. IoT enables seamless connectivity and communication between devices, leading to smarter and more efficient industrial processes. Industry 4.0, characterized by the use of cyber-physical systems, further enhances automation by enabling real-time data analysis and decision-making. These technologies facilitate predictive maintenance, reducing downtime and operational costs. By leveraging IoT and Industry 4.0, companies can achieve higher levels of automation, resulting in improved productivity and reduced human error.

With the increasing adoption of IoT and Industry 4.0, industries can optimize their processes through real-time monitoring and control. This not only enhances efficiency but also ensures timely interventions, which significantly minimize the risk of equipment failure. The ability to make data-driven decisions allows industries to operate more smoothly, with fewer disruptions. Consequently, the automation instrumentation market is witnessing substantial growth as more companies integrate these advanced technologies into their operations, leading to a more interconnected and responsive industrial environment.

Advancements in Sensor Technology

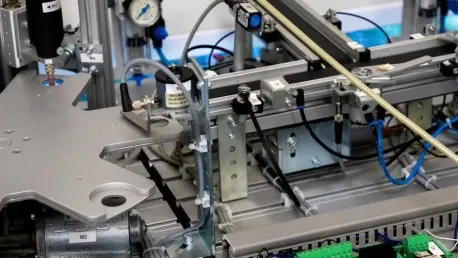

Sensor technology has seen remarkable advancements, contributing significantly to the growth of the automation instrumentation market. Modern sensors are more accurate, reliable, and capable of operating in harsh environments. They play a crucial role in monitoring and controlling industrial processes, ensuring optimal performance and safety. The development of smart sensors, which can communicate data in real time, has further enhanced the capabilities of automation systems. These sensors provide valuable insights into process conditions, enabling timely interventions and adjustments.

In addition to enhancing operational efficiency, advanced sensor technologies help in maintaining stringent safety standards. This is particularly important in industries such as oil & gas and manufacturing, where precision and reliability are paramount. As industries strive for higher productivity and reduced downtime, the demand for cutting-edge sensors has surged, bolstering the growth of the automation instrumentation market. Furthermore, the ability of smart sensors to adapt to various industrial requirements ensures their widespread adoption, solidifying their role as a cornerstone of modern industrial automation.

Market Demands

Expansion of Smart Factories

The rise of smart factories is a major driver of growth in the automation instrumentation market. Smart factories leverage advanced automation technologies to create highly efficient and flexible manufacturing environments. These factories rely on automation instrumentation to monitor and control various processes, ensuring seamless operations. The demand for smart factories is increasing as companies seek to improve their competitiveness and adapt to changing market conditions. Automation instrumentation is essential for achieving the high levels of efficiency and precision required in smart manufacturing.

Smart factories represent the next evolution in manufacturing, where automation, data exchange, and advanced technologies converge. This results in a highly responsive and adaptable production process, capable of meeting the ever-evolving demands of the market. Industries are increasingly transitioning towards smart manufacturing to gain a competitive edge, reduce operational costs, and enhance product quality. As a result, the proliferation of smart factories is fueling the growth of the automation instrumentation market, driving innovation and shaping the future of manufacturing.

Increasing Demand for Industrial Automation

Industrial automation is becoming increasingly important across various sectors, including manufacturing, oil & gas, and process control. The need for higher productivity, cost reduction, and improved safety is driving the adoption of automation instrumentation. Automation systems equipped with advanced instrumentation can perform complex tasks with minimal human intervention, leading to significant improvements in operational efficiency. The growing emphasis on industrial automation is a key factor contributing to the market’s expansion.

Automation instrumentation enables industries to streamline their operations, resulting in faster production cycles and reduced labor costs. This is particularly crucial in industries where precision and consistency are essential. By minimizing human error and optimizing resource utilization, automation systems contribute to substantial cost savings. Consequently, the increasing need for industrial automation across various sectors has propelled the automation instrumentation market, as companies recognize the benefits of integrating these advanced systems into their workflows.

Industry Trends

Growth of Predictive Maintenance

Predictive maintenance is an emerging trend that is gaining traction in the automation instrumentation market. This approach involves using data analytics and machine learning to predict equipment failures before they occur. By implementing predictive maintenance, companies can reduce unplanned downtime, extend equipment life, and lower maintenance costs. Automation instrumentation plays a critical role in predictive maintenance by providing real-time data on equipment performance and condition. The adoption of predictive maintenance is expected to drive further growth in the market.

By leveraging predictive maintenance, companies can adopt a more proactive approach to equipment management. This not only enhances operational efficiency but also ensures optimal asset utilization. The ability to foresee potential issues and address them before they escalate into significant problems translates to substantial cost savings and increased equipment reliability. As industries continue to recognize the value of predictive maintenance, the demand for automation instrumentation that supports such capabilities is likely to surge, further fueling market growth.

Adoption of Advanced Control Systems

Advanced control systems are becoming increasingly popular in the automation instrumentation market. These systems use sophisticated algorithms and real-time data to optimize industrial processes. They offer greater precision and flexibility compared to traditional control systems, enabling companies to achieve higher levels of efficiency and productivity. The adoption of advanced control systems is driven by the need for improved process control and the desire to stay competitive in a rapidly evolving market. As more companies recognize the benefits of these systems, the demand for automation instrumentation is expected to rise.

Advanced control systems provide a significant advantage by enabling real-time adjustments and process optimization. This capability is particularly beneficial in industries where even minor deviations can result in substantial losses. By ensuring consistent performance and maximizing resource efficiency, advanced control systems help industries maintain high standards of quality and productivity. As a result, the growing adoption of these systems is a critical driver of the automation instrumentation market, as companies seek to capitalize on the efficiencies and competitive advantages they offer.

Market Challenges

High Implementation Costs

Despite the numerous benefits of automation instrumentation, high implementation costs remain a significant challenge. The initial investment required for installing and integrating advanced automation systems can be substantial, particularly for small and medium-sized enterprises (SMEs). These costs include not only the purchase of equipment but also expenses related to system integration, training, and maintenance. While the long-term benefits often outweigh the initial costs, the financial barrier can hinder market growth, especially for smaller companies.

For SMEs, the financial burden associated with implementing automation systems can be a considerable deterrent. The need for substantial upfront investment can limit their ability to adopt these technologies, even when the potential benefits are evident. To address this challenge, companies and governments are exploring various strategies, including subsidies, grants, and innovative financing models to lower the financial barriers to automation adoption. Overcoming these challenges is crucial for the sustained growth of the automation instrumentation market, as broader accessibility will drive wider adoption across various industries.

Skilled Labor Shortages

The shortage of skilled labor is another challenge facing the automation instrumentation market. As automation technologies become more advanced, the demand for skilled professionals who can design, implement, and maintain these systems is increasing. However, there is a growing gap between the demand for skilled labor and the available workforce. This shortage can slow down the adoption of automation instrumentation and limit the market’s growth potential. Addressing this challenge requires investment in education and training programs to develop the necessary skills.

To bridge this skills gap, industries, educational institutions, and governments are collaborating to develop specialized training programs that equip the workforce with the expertise needed for modern automation technologies. Apprenticeships, certifications, and hands-on training initiatives are being promoted to ensure that the labor market can meet the evolving needs of the automation sector. By fostering a highly skilled workforce, industries can accelerate the adoption of automation instrumentation, driving innovation and ensuring long-term growth in the market.

Geographical Insights

Established Markets in North America and Europe

North America and Europe are established markets for automation instrumentation, driven by the presence of major industry players and advanced industrial infrastructure. These regions have a high adoption rate of automation technologies, supported by strong regulatory frameworks and significant investments in research and development. The mature markets in North America and Europe continue to grow, driven by ongoing technological advancements and the need for modernization in various industries. Companies in these regions are focused on enhancing their automation capabilities to maintain their competitive edge.

The well-established industrial base in North America and Europe provides a solid foundation for the widespread adoption of automation instrumentation. These regions benefit from a robust ecosystem of suppliers, manufacturers, and service providers that support the integration and maintenance of advanced automation systems. Continued investments in innovation and a commitment to maintaining high standards of quality and safety ensure that North America and Europe remain at the forefront of the automation instrumentation market, driving growth and setting industry benchmarks.

Rapid Growth in Asia Pacific

The automation instrumentation market in the Asia Pacific region is experiencing rapid growth, driven by increasing industrialization, urbanization, and economic development. Countries like China, India, and Japan are investing heavily in modernizing their industrial processes and infrastructure. The demand for automation instrumentation is rising as industries in this region seek to improve efficiency, productivity, and competitiveness. Additionally, favorable government policies and initiatives promoting advanced manufacturing technologies are further boosting the market’s growth prospects.

As Asia Pacific continues to develop as a key player in the global economy, the region’s focus on innovation and modernization is driving the adoption of automation instrumentation. The presence of a large and skilled workforce, along with significant investments in research and development, positions Asia Pacific as a critical market for future growth. The dynamic and rapidly evolving industrial landscape in this region offers ample opportunities for companies involved in automation instrumentation to expand their presence and capitalize on the growing demand for advanced automation solutions.

Overall, the automation instrumentation market is witnessing robust growth due to various factors that enhance efficiency, precision, and safety in industrial processes. Leading this growth are technological advancements, which have revolutionized how industries operate by streamlining complex processes and minimizing human error. Market demands are also driving expansion as industries seek to improve production rates and quality control. Customers increasingly expect faster, more reliable, and accurate outputs, prompting businesses to invest in advanced automation solutions. Additionally, industry trends like the Industrial Internet of Things (IIoT) and smart manufacturing are playing critical roles in propelling the market forward. These trends emphasize the integration of high-tech instruments and real-time data analytics to enhance operational efficiency and predictive maintenance capabilities. This comprehensive exploration of the automation instrumentation market highlights the crucial impact of technological developments, evolving market needs, and progressive industrial trends in fostering sustainable growth and innovation in this dynamic sector.